The Value of Expertise in Plush Toy Manufacturing

Forty Years of Expertise Ensures Reliability and Trust in Plush Toy Production

According to the Industry Benchmark Report from 2023, companies that have been around for many years actually cut down on mistakes by about 42% when compared to those just starting out. These established firms know their stuff inside and out, which helps them pick better materials and set up proper testing methods tailored specifically for their products. They tend to avoid problems that plague newcomers, such as weak seams or uneven stuffing in stuffed animals. The result? More consistent results overall and less need for expensive fixes later on. Take toy manufacturers for example those operating for more than four decades typically get their products right on the first try most of the time, hitting that impressive mark of 98.6% compliance with important safety regulations like EN71 and ASTM F963 according to data found in the Global Toy Compliance Review.

Experienced Teams Accelerate Time-to-Market With Streamlined Workflows

Seasoned production crews cut out around 15 to maybe even 25 unnecessary steps that new teams often include in their workflows. These pros have built up all sorts of reliable methods from working on literally thousands of stuffed animal projects over the years. Their toolkit includes things like regular design checks at key points, well-established connections for getting materials, and assembly lines set up just right for maximum speed. All this experience means products go from concept to finished goods about a month faster than average, sometimes even cutting down wait times by nearly two months. For companies trying to get toys on store shelves before holidays, this kind of time savings can make or break their sales season.

How Deep Industry Knowledge Improves Scalability and Production Decisions

Manufacturers who have been around for years typically have backup plans ready for most supply chain issues that come up. Looking at industry stats, these companies handle about 9 out of 10 common disruptions without major problems. The reason? They've built up tons of historical data over time which helps them predict what might happen next. This experience leads to better planning and actually cuts down on wasted materials by roughly 22%, mainly because they can figure out exactly how much stuff to order at once. Scaling production from small runs of 5,000 items up to massive batches of half a million units doesn't affect quality either. Skilled partners keep the same stitching pattern throughout everything they make, maintaining between 9 and 12 stitches per inch. This level of consistency is pretty standard in the textile world according to most engineering guidelines, but it makes a real difference when customers expect the same quality whether buying one item or thousands.

Superior Craftsmanship: Precision and Durability in Every Stitch

Skilled Artisans Bring Attention to Detail That Defines High-Quality Plush Toys

The best manufacturers rely on techniques such as single needle stitching, which is pretty much the benchmark for quality work in textiles, to get those clean seams and fibers that line up just right. When done properly, this kind of attention gives products symmetrical embroidery patterns, consistent stuffing throughout, and those nearly invisible joins that factory made items usually miss entirely. Skilled workers who've spent years working with fabrics notice tiny tension issues in materials that machines simply cannot pick up on. These small corrections make all the difference in how durable and well made something feels when it reaches consumers.

Expert Craftsmanship Enhances Durability and Long-Term Performance

Toys crafted by experienced makers last anywhere from two to three times longer when put through ASTM F963 safety tests compared to cheaper options on the market. What makes them stand out? The real magic happens at those trouble spots we all know too well - ears, limbs, and seams. These are actually where most damage tends to happen during playtime, as recent studies from 2023 showed something like 78% of all wear occurs right there. Skilled artisans combine heavy duty threads with carefully tied knots to build plush friends that stay fluffy and keep their shape even after countless hugs, multiple washes, and whatever rough handling kids throw their way day after day.

Case Study: Stitch Quality Comparison Between Novice and Experienced Manufacturers

Looking at 500 plush toys in 2024 showed something interesting. Products made by companies with over a decade of experience had almost two thirds fewer defects compared to newer manufacturers. The ones that stuck with time tested reinforced stitching techniques performed much better too. When pulled apart in testing, these seams held up 40% stronger than regular stitching. Even after being squished multiple times, they kept 98% of their stuffing inside without leaking out. All these tangible differences mean stuffed animals last longer before falling apart. Kids (and adults) tend to be happier with their purchases when the toy doesn't start coming apart after just a few weeks of playtime.

Advanced Customization Through Proven Design and Production Experience

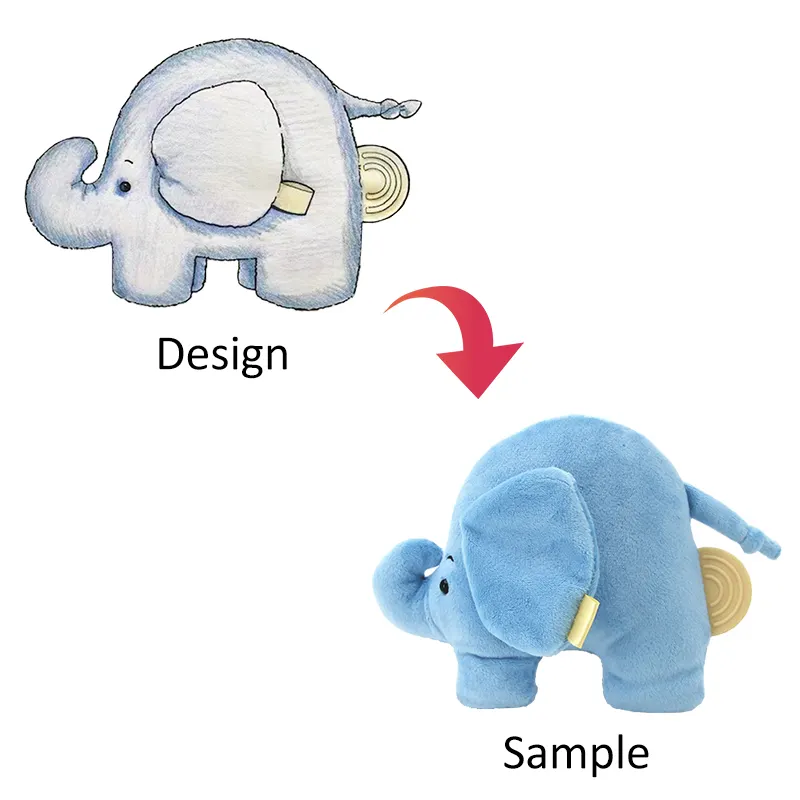

OEM/ODM Customization Powered by Decades of Innovation in Plush Toys

Seasoned manufacturers blend 40+ years of technical know-how with modular design systems to deliver tailored OEM/ODM solutions. By integrating AI-driven prototyping tools, they reduce concept-to-sample lead times by 35% while ensuring full compliance with child safety regulations—a non-negotiable priority in toy development.

End-to-End Design-to-Delivery Workflow of Expert Plush Toy Makers

Established producers utilize vertically integrated workflows that align material sourcing, precision stitching, and automated quality control. This cohesion eliminates communication gaps between design and manufacturing teams, reducing revisions by 22% compared to fragmented production models.

From Concept to Creation: How Experience Elevates Custom Plush Toy Outcomes

Veteran teams apply historical insights on fabric wear patterns and stuffing density to enhance durability. A 2023 wash-test analysis showed plush toys from experienced manufacturers retained structural integrity 40% longer than those from less experienced producers, directly boosting customer satisfaction and reinforcing brand trust.

Rigorous Quality Control and Compliance with Global Safety Standards

Strict Quality Control Processes and International Certifications Ensure Safety

Seasoned manufacturers of plush toys put in place several layers of inspection that go well beyond what basic regulations require. Independent auditors check if companies follow ISO 9001 quality management practices as well as specific toy safety standards from different regions. Think about EN71 for European markets, ASTM F963 here in the US, and CCC certification needed for Chinese exports. Looking at data from the CPSC in 2023 shows something interesting: factories with ISO certification had around 62 percent fewer product recalls compared to those without it. All these checks are there to make sure toys meet safety standards regarding things like choking risks, how they handle fire exposure, and maintaining good stitching throughout entire batches of production.

Experienced Teams Prevent Defects Through Precise Material and Process Selection

Seasoned production folks have been sifting through years worth of material test results to pick out fabrics that won't irritate skin and stuffing that can take a beating for over 100 thousand compressions before losing shape. They cross check every component against their own secret database containing around 12 thousand different materials, which cuts down on failures by nearly a third when compared to companies just starting out in this space according to last year's Global Plush Materials Report. What these experts know inside out includes special dye treatments that stop colors from running all over the place, something absolutely critical if products need to pass those strict CPSIA safety tests regarding heavy metals and other chemicals.

Consistent Adherence to Safety Standards Driven by Seasoned Production Staff

Companies that have been around for over a decade typically hit about 98.6% compliance with all those international safety standards out there, and they keep their staff trained every three months or so. According to some research done by folks at the International Toy Safety Consortium, factories where certified quality engineers are on board actually report around 18% fewer problems with following protocols compared to places that just depend on automated systems. Having people involved makes all the difference when it comes to keeping up with changing rules like California's Proposition 65 requirements or dealing with the EU's complicated REACH restrictions on substances. Real humans catch things machines might miss, especially when regulations get updated regularly.

Strategic Branding: Leveraging Plush Toys for Customer Engagement

Expertise in Creating Promotional Plush Toys That Strengthen Brand Identity

Manufacturers who really know their stuff blend good design with what the market wants when creating promotional plush toys that actually match what a brand stands for. Companies that have been making soft toys for over 15 years tend to produce mascots and special edition items that people connect with. Take a look at some research from 2023, which found that brands using custom made plush toys saw about 34 percent better brand recall compared to companies stuck with generic merchandise options. What makes this work is how these experts can weave in company logos, color schemes, and even the brand's overall vibe into something customers can touch and feel emotionally.

High-Quality Plush Toys as Effective Tools for Branding and Customer Loyalty

Good quality plush toys can stick around as brand representatives for quite some time. According to recent data from the Promotional Products Association (2024), about seven out of ten people hold onto nice quality promotional stuff for more than two years. When parents see strong stitching and safe materials in these toys, they tend to think the company knows what it's doing. After all, who wants their kids playing with something flimsy? Some businesses have found that adding fancy plush toys to their loyalty programs works wonders. One study showed a nearly 20% jump in repeat purchases when customers got those soft, well-made toys. People just seem to remember the brand better when they associate it with something comfortable and well crafted.

FAQ Section

Why is decades of experience crucial in plush toy manufacturing?

Decades of experience helps manufacturers reduce mistakes, improve material selection, enforce compliance with safety regulations, streamline workflows, and enhance product scalability.

How do skilled artisans impact plush toy quality?

Skilled artisans bring attention to detail, resulting in plush toys with clean seams, consistent stuffing, and enhanced durability. Their craftsmanship ensures products last longer even with heavy use.

What benefits come from advanced customization in plush toys?

Experienced manufacturers offer OEM/ODM customization with faster lead times, modular design systems, and compliance with safety regulations, ensuring tailored products that align with brand identity.

How do established manufacturers ensure toy safety?

They enforce strict quality control measures, undergo multiple layers of inspections, and maintain compliance with international certifications to minimize risks and ensure product safety.

How can plush toys enhance branding?

Customized plush toys strengthen brand identity by incorporating logos and colors, enhancing brand recall and customer loyalty through emotional and tactile connections.

Table of Contents

- The Value of Expertise in Plush Toy Manufacturing

- Superior Craftsmanship: Precision and Durability in Every Stitch

- Advanced Customization Through Proven Design and Production Experience

- Rigorous Quality Control and Compliance with Global Safety Standards

- Strategic Branding: Leveraging Plush Toys for Customer Engagement

- FAQ Section

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

EU

EU

BN

BN

LO

LO

LA

LA

SO

SO

KK

KK